| Product Details |

| Running Video |

| Connect Drawing |

|

| Features |

| 1.Feed system of 4liter tank(0.5 liter, 2liter,4liter,20liter). 2.Intelligent dispense software allows the user more control over dispensing applications. 3.Has an analog timer with a knob to arrive dosing require. 4.Precision suck-back valve.close glue quickly,ensures no dripping. 5.The pedal /ring/inductive switches can be chosen. 6.Complete with an accessory dispensing kit. |

| Application |

|

Packing capacity:tank (0.5liter,2liter,4liter.20liter can option) |

|

Liquid Material:adhesive, glue, uv glue,oil |

| Specification |

| ITEM | TH-2004KJ |

| Standard | CE Approved |

| Control | E-pneumatic |

| Operating Model | Manual, Timer, cycles |

| Feed system | (0.5liter,2liter,4liter.20liter can option) |

| Leak-proof function | valve with Vacuum device |

| Control way | Foot Pedal, Finger Switch |

| Valve | TH-600J or TH-100J |

| Dispensing time | 0.001 - 9.999S |

| Repeatability | +/-0.01% |

| Frequency | 300 times/minute |

| Input Air pressure | 1-7 bar (100 psi) maximum (1bar =1.01972kg/cm² =14.5038psi) |

| Air output | 0.1bar-0.7bar |

| Input voltage | 110/220VAC |

| Output voltage | 24VDC |

| Power | 15W |

| Temperature | 5°C to 45°C (41°F-113°F) |

| Humidity | 85% RH at 30°C non-condensing |

| size | 24.10x21.00x7.00cm |

| Weight | 3KG |

| Advantage |

| Export CE certification, has been sold for 15 years. |

| 304 Stainless steel reservoir tanks are designed to maintain a steady fluid pressure for most dispensing applications, while providing excellent protection against corrosion or contamination. |

| Imported Norgnenl Precision pressure regulator, the output pressure is stable, better to ensure the stability of the dispensing machine. |

| Precision suck-back valve.close glue quickly,ensures no dripping. |

| Detail |

|  | |

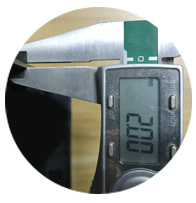

| Dedicated voltage stabilizing circuit Design.Guarantee the stability of the machine. | The body is oxidized with 2mm thick aluminum plate. | |

|  | |

| Use of metal quick connectors, loading and unloading more convenient, durable. | Thickened pearl cotton inner packaging,Ensure the safety of the machine during transportation. |

| All screws on the machine are made of 304 stainless steel material, the rust and corrosion resistance is not easy to slip. The fixation of each screw is tested by the torque test tool. |

| Connect wiring standard requirement with Euro CE Export certification, To ensure long-term stability and reliability of the machine. |

| Standardized production process documents, each machine output is strictly check controlled by more than 500 procedures. |

| Every production inspection process comes from the accumulated experience of engineers. that can guarantee the long-term stable operation of Tianhao dispensing controller. The Tianhao dispensing controller delivered to customers are all escorted by the teamwork of all Tianhao dispensing employees. |

| After Sales Service And Warranty |

| Service: Your satisfactory, our pursuit! The quality and good service is in higher level for us to satisfy our customer. | |

| 1. | Machine question will be replied in 24 hours. |

| 2. | We provide 1 years warranty of machine,Lifelong maintenance. |

| 3. | Free video trial. Just send us a sample of your part and material and our lab will record the trial, demonstrate the robot in action, provide the process data, and send you the video with completed parts. |

| 4. | Provide Demo operation video for training; If you have time, welcome to our company,we offer free training how to install the machine, training how to use the machine, our company Will arrange engineers to show you the operation. |

| 5. | Our Engineers available to service machinery overseas ,we can offer oversea training and install for customer, when machine running in your company have no question, then our engineer will back. |

| 6. | After shipping, we will track the products for you once every two days, until you get the products. When you got the goods, test them, and give me a feedback.If you have any questions about the problem, contact with us, we will offer the solve way for you. |

| 7. | Each machine spent 3 weeks make running testing before shipping, then keep machine good work. |

| 8. | Convenient: |

| 1).Operation simple and convenient. Cleaning is convenient. 2).Production management is convenient,Machine is able to operate without PC control ,The teach pedant is portable, place it in a safe place, in case of staff misuse. 3).Service convenient ,All machine modular design, easy to replace new parts.each parts single replace,but no effect complete machine. 4).Software design very simple and easy to remote control. our company have oneself software engineer. | |

| Value-added Services |

| Free Free offer trial video for your sample Free training with machine Free offer accessories dispensing kit One machine instead of three or four staff, reduce the management cost, also can work for 24 hours. Staff no need direct contact with glue material,so not need work with face masks,Improve the working environment. When bring customers to visit your workshop,the equipment to produce customer satisfaction products,then take good business for you. Fast |